The 21st Century Digital Home

Anne Barela's posts on electronics, including vintage, modern, and Internet of Things projects.

Wednesday, March 15, 2023

Sunday, February 5, 2023

Vintage HP Disc Memory Division T-Shirt 1983

I worked for the HP Disc Memory Division in Boise Idaho, during the summers of 1981, '82, and '83. It gave me the money to almost afford to go to Whitman College prior to attending Caltech the following two years under a 3-2 Engineering Program.

In 1981, I worked with a microscope 8 hours a day soldering wires on disc heads. In '82 & '83, I worked on the HP 7933/7935 disc drive (Wikipedia) assembly line. I did multiple jobs, wherever they needed me: installing blower motors, making the assembly the disc packs went in ("the tub"). The units were the size of a small dishwasher. And they were finicky to make. They had 7 platters, 14 heads, so a lot could go wrong. When they failed burn-in testing, they'd be sent back to change out a possible defective part. It kept us very busy!

I think the shirt above is my only one to survive to this day. It has the HP logo on the front. On back it has a person holding up a barbell with words depicting issues encountered. The text says "B.F.D. does it under pressure". BFD referred to the unofficial name HP gave the HP7933/35 units: "Big F'in Drive". At 404MB, it was much larger than previous units (the HP7920 had 50MB).

If anyone is interested in this piece of Hewlett-Packard history, contact me on Twitter @anne_engineer or Mastodon @anneb@octodon.social.

IBM 5170 PC/AT Upgrades

Tuesday, January 10, 2023

Buying an Old IBM PC or Compatible on eBay or in Person - tips

Buying old computers is always a bit of a gamble, as is buying used items made so long ago. As long as you go into buying mode with the expectation that things may go well or not so well, you'll be best prepared for the results.

So you browse eBay or Craigslist, or go to a boot sale or Ham swap meet. There is an old IBM or compatible computer you're interested in. Here are some tips that may help you in the buying evaluation process.

1. Is it running? - Likely "no way to test" as few rarely have all the parts, period correct display, etc. Here is a list of running conditions:

- No power applied

- Powered up, fan spins on power supply

- Computer beeps on power up

- Hard disk and/or floppy sounds

- Some display says it "boots" to BASIC

- Some display says it shows errors or boots MS or PC-DOS

Each level down is better than the last. If there is a hard disk and it boots to DOS, that's best. Boots from floppy second, and so on. This gives you confidence in the motherboard, power supply, disk controllers, etc. More confidence in working hardware = more valuable (to you - always keep this info to yourself).

2. Exterior Visual Inspection - Why is this #2? Because #1 provides more information at first inspection.

Look at the pictures, or if you're lucky in person. Case condition counts - are there screws holding things, items loose, accessories if any.

Important: Look at the rear panel. See what add-in cards you can see from the outside. It's a really good indicator of what comes with the machine. And sellers most often have no clue and don't price up with "good cards" inside, full memory, or a coprocessor. This is the first IBM PC/AT I bought. The price was good and I was intrigued at the cards:

Here you can see a lot of good info: It's a later model AT from the 512K System board. It has a Seagate ST-225 hard drive, half height, no 80287 coprocessor and lots more interesting card info. The most valuable cards are memory. The cards are, from the left, the floppy/hard drive controller, standard, IBM serial/parallel adapter, common, an IBM 128k memory board (brings memory to 640K, good!) the 10-Base T network card, an IBM Token Ring network adapter, and the far card was a dual board strange beast, which turned out to be a Wyse 700 display card, pricey in the day.

Wow, this is better than average. The extra memory is the main bonus. Unfortunately the card doesn't hold more than 128k. The network cards are not immediately useful and the rare display card not immediately useful either (but commands $90 to $150 on eBay).

So the inspection lets you know how much bang for the buck you get. Add this to the info in previous steps.

NOTE: Unless it boots with hard drive access via a display, never assume the hard drive works. Most often they have died due to age or transit. The red light might come on, it doesn't count really. This is not a huge deal breaker as there are solutions to use memory cards holding much more instead. But a working hard drive is excellent, one with application software more so. Floppies can also not be working with dirty and/or misaligned heads. This is all about 40 year old hardware.

4. Cleanliness - if it's cleaner than not, that's great. Also if it doesn't smell like cigarette smoke or says "smoke free environment" that's good too. I had one machine that had an old insect infestation, yuck.

Ready to Decide

Ok, based on the information you have, you then need to decide if you want it. You don't want to show much emotion to the seller. Of there is a process to offer a price, you can start lower than their price. Then again, if you see lots you like, you might just want to pay their price, if reasonable.Know that you'll need a keyboard, display, cabling often to be able to check it out, those all cost extra, usually from other buyers. Factor that into your budget. I usually look to buy a used VGA card and hook it to a more modern LCD display with VGA connection. Keyboards can be very expensive especially for genuine IBM, but some knock-offs can be reasonable. On this machine, I got the seller to throw one in for free.

Then you use the methods for haggling and buying familiar to most people. Don't like it, don't buy it. If you find some utility, look to pay what is useful to you, which may be less than they want. If they want too much, there are likely others out there. If you see something rare about the machine, factor that into your price.

Usually there is enough stock on the market to have a pick. At the time this is being written, a drought on IBM PC/AT machines appears over and they are selling for around $300 US just the system unit. But not all machines are the same, hence the review. Also price rises depending on #1 - if it's running. Don't expect a $300 machine that boots to DOS 6.22 with a ton of software and memory. If you can find one, it's a true bargain.

Shipping

Buying in person saves money. Unfortunately these computers are heavy and shipping can be costly. If an auction says shipping free (or at a low cost), factor that as a positive. If shipping is too much, you might want to pass. And likely if the hard drives with my two PC/ATs ever worked, the harsh shipping that likely ensued trashed them.

The buyer could park the drive heads or pack the drive in a secure box but that would be very rare and command more money as most will not do such.

Good Luck

From minuszero.net - some tips on language used on auction sites:

"Extremely rare"

Example: I would list one of my toenail clippings as extremely rare, because only my clippings contain my DNA.

"Includes a certificate of authenticity"

Useful for proving the authenticity of an item that you are selling.

For example, I provide a Certificate of Authenticity with every "Genuine Loch Ness Monster's Tooth" that I sell.

"Pulled from a working system"

working = I turned the system on, and I either heard the power supply fan turning, or I saw a light somewhere turn on. No smoke was evident.

"It was working the last time I powered it on"

Meaning #1: It does not work now. I will say that it it worked the last time I powered it on. When the buyer complains, I will say that it was working 5 years ago, and must have deteriorated in that time. Meaning #2: I have no idea how to tell if it is working or not. But, I think there's a good chance that it is working. I do not want to list it as untested because that will put a lot of people off. I will list it as, "It was working the last time I powered it on", and take my chances.

Sunday, January 8, 2023

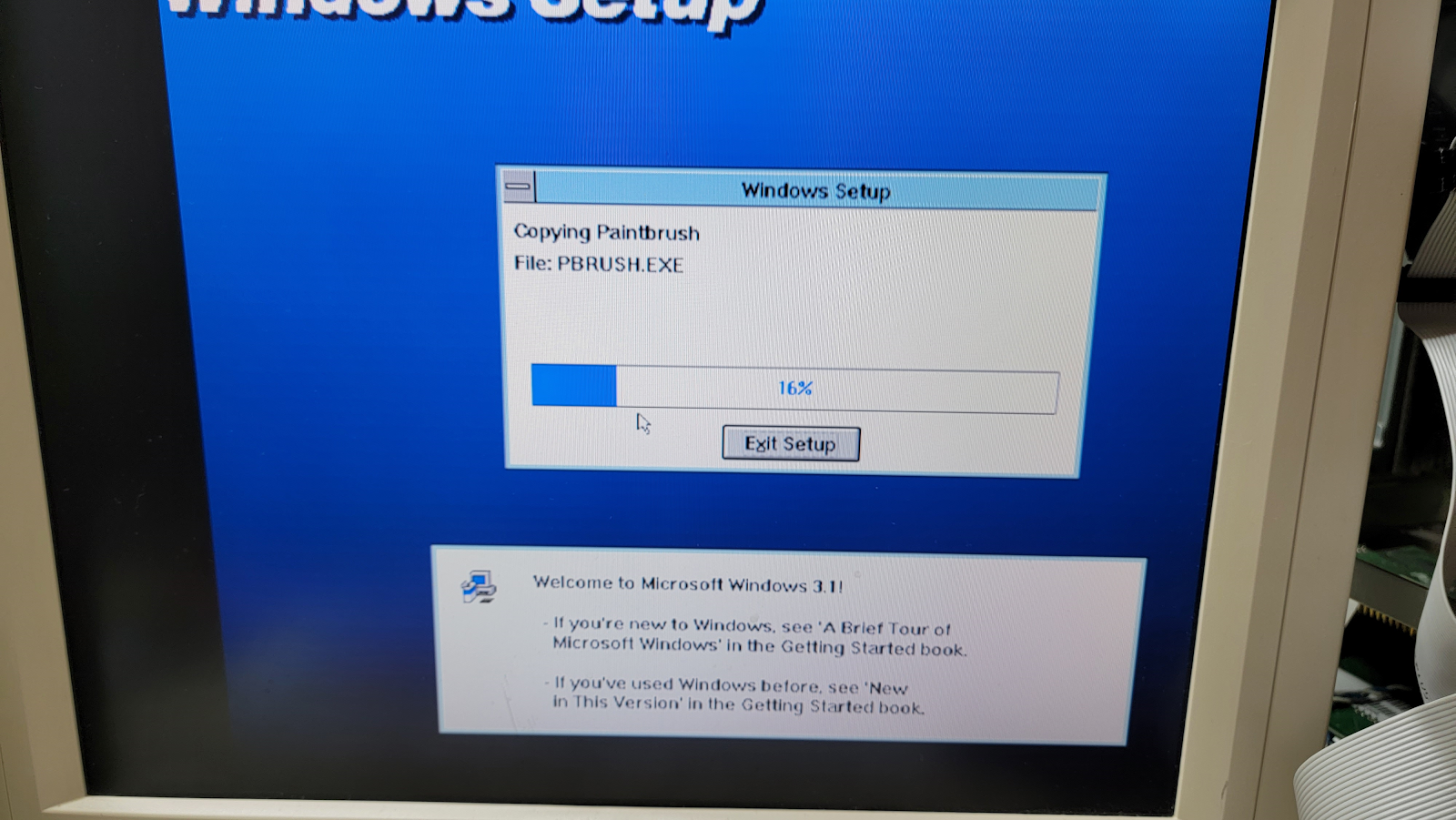

Upgrading the IBM PC/AT to MS-DOS 6.22 and Windows 3.1

You read this correctly. What a software upgrade. My floppies for Windows/286 seem damaged. so...

Going from MS-DOS 5 to MS-DOS 6.22

Once I got the 1.44M floppy recognized, the 1.44MB MS-DOS 6.22 upgrade diskettes read correctly and the install process ran fine. DOS 6.22 takes up more memory but has some nice utilities and is the most state of the art version (to my knowledge).

Installing Windows 3.1 on an IBM PC/AT

Getting the IBM PC/AT to Recognize a 1.44MB Hard Disk

Lots of time this week getting my IBM PC/AT up to speed. Here's a synopsis:

Getting a New Compact Flash Hard Drive

Instead of the XT-IDE Compact Flash hard disk adapter, I switched it for a modern XT-IDE Rev 4 IDE controller card and an IDE to Compact Flash adapter. This way I can use a spinning IDE adapter or whatever later and use the old adapter in an XT machine. Much fiddling with jumpers and it worked. Same shenanigans getting it to be bootable. My latest trick is boot to DOS 3.1 then upgrade to DOS 5. That seems to work well. I now have a 128MB Compact Flash SSD working in the AT.

Getting the Sony 1.44MB 3.5 inch disk drive working

Even though my machine is the latest revision of the PC/AT made, with a BIOS dated 11/15/1985, the IBM Diagnostics Diskette (version 2.03) setup only has 360k, 1.2M and 720k floppy drive options. The BIOS does have code for 1.44M 3.5" drives. But how to set that? I went back to minuszerodegrees.net here and there is a third party program called GSETUP.EXE that can set the right drive type. Yay!

I just needed it on my Compact Flash hard drive. To do so, I used my Tweener Pentium III/500 to read the file off a thumb drive then write it to the Compact Flash card via a USB to Compact Flash card adapter. Yes, this is a lot of hardware for this type of work. I could have copied it to the Compact Flash from my modern desktop but I'm not that smart. It did allow me to copy GSETUP to my MS-DOS 5 boot floppy - likely why I chose that route.

With GSETUP.EXE, I ran it (no special boot required and indeed I could chose 1.44MB 3.5" drive as a choice for drive B. Then I could read and write high density 3.5" drives like I should. Yay!

See the next installment for upgrading DOS & more.

Tuesday, January 3, 2023

Getting a non-functional IBM PC/AT up and running is hard

It's been a long time without posts. Maybe I can correct this.

A couple months ago, I took the plunge and got an IBM PC/AT. I've wanted one for almost 40 years. I have an IBM PC, two PC/XTs, and a 5160 portable. A 5170 is next in line ATs were very hard to get for the last couple years but units are showing up on eBay with various descriptions, usually untested. No keyboard, monitor, cables, etc. So one goes off a few pictures and hopes for the best.

I get an XT-IDE ISA to compact flash card and put in a 16MB CF card. I had issues with that until I used the XT CD-ROM in the Pentium III to mark the drive via FDISK /MBR. Then I could format the drive and I loaded PCDOS 2. I upgraded it via floppy to MS-DOS 5.0. There are a slew of XT-IDE cards out there and some don't play nice with the AT without clone ROMs which would be a huge headache. So I'm glad the one I have played ok.

Meanwhile, I didn't turn my alert off on eBay and another IBM PC/AT machine popped up at a good price. Amy bought it for me for a birthday present. It has parts that complement the PC above. I'll dive into that one in the next post.